Latest figures from UKIFDA, a partner in the project, show 130 properties are participating, nine of which are non-domestic properties, all demonstrating the value of using HVO.

UKIFDA recently reported they were on target to meet the project’s fuel distribution quota of c300,000 litres by the end of 2022. All properties converted as part of the demonstration have been supplied with HVO, free of charge, by fuel distribution members taking part in the demonstration. Each property converted has had its heating boiler or cooker monitored for performance and efficiency and reports containing data are sent to OFTEC for scrutiny and analysis. The appliances operating on HVO also receive a routine annual service by the participating fuel distribution companies, so that any irregular operation can be observed by the service technician, and any issues encountered or experienced by the property occupier can be reported back to OFTEC for analysis.

Justifiable optimism

The initial optimism that HVO would be a near drop-in replacement for kerosene has proved to be entirely justified. The use of HVO in the project has been extremely successful and, apart from some minor upstream fuel contamination issues reported – which have been analysed by a laboratory – the demonstration has fully achieved its technical goals, providing excellent carbon emission reductions by up to 90%.

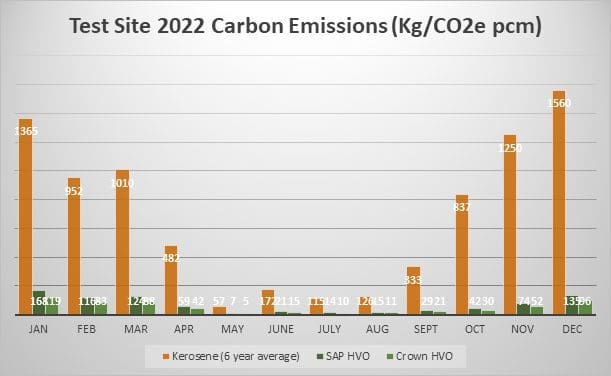

To demonstrate carbon savings reliably, OFTEC required a control site in which to demonstrate carbon emissions. A test site was chosen, and a modern boiler and controls installed, which could be relied upon to provide reliable data of HVO fuel consumption, heating trends and emissions which could be analysed on a month-by-month basis. The output of which has been generated below as a graph which shows CO2 emissions savings compared to kerosene over a full 12-month period.

Data analysis

To accurately calculate HVO emissions and further explain calculation methodology, the Building Research Establishment (BRE) was asked to evaluate carbon emissions from waste derived HVO provided by Crown Oil Ltd, and to produce a generic waste estimated UK typical value for inclusion in SAP 10, utilising the BRE methodology S10TP-15

BRE evaluated the HVO carbon equivalent emissions:

Used cooking oil only derived HVO (Crown HVO) = 0.025 kg CO2e per kWh

Generic waste derived HVO (SAP HVO) = 0.036 kg CO2e per kWh

The values are then used to compare average kerosene usage against HVO measured fuel usage (x SE x BRE CO2e values) to give comparative monthly and annual emission values.

SAP 10.2 Table 12 Kerosene = 0.298 kg CO2e per kWh

N.B. The SAP Primary Energy Factor (PE) is the same for HVO and kerosene.

The OFTEC HVO Demonstrator control site has achieved a near 30% improvement in the Energy Performance Rating of the 300-year-old, off gas grid “hard to treat” rural property, from a Band D to a Band C, simply by applying modern liquid fuel fired appliances and controls as a direct end of life replacement of existing liquid fuel fired equipment.

Follow up

A further report will be published by OFTEC to explain the full details about the study. The report will provide technical details about the conversions, the fuel characteristics, tanks, sustainability, and a Publicly Available Standard (PAS), ending with a conclusion and recommendations to further make the case for HVO.